The Zinkphosphat primer which I use to cover my aluminium parts usually takes days to cure. And even then the surface remains sensitive to scratching. The alternative: Anodizing. Self made.

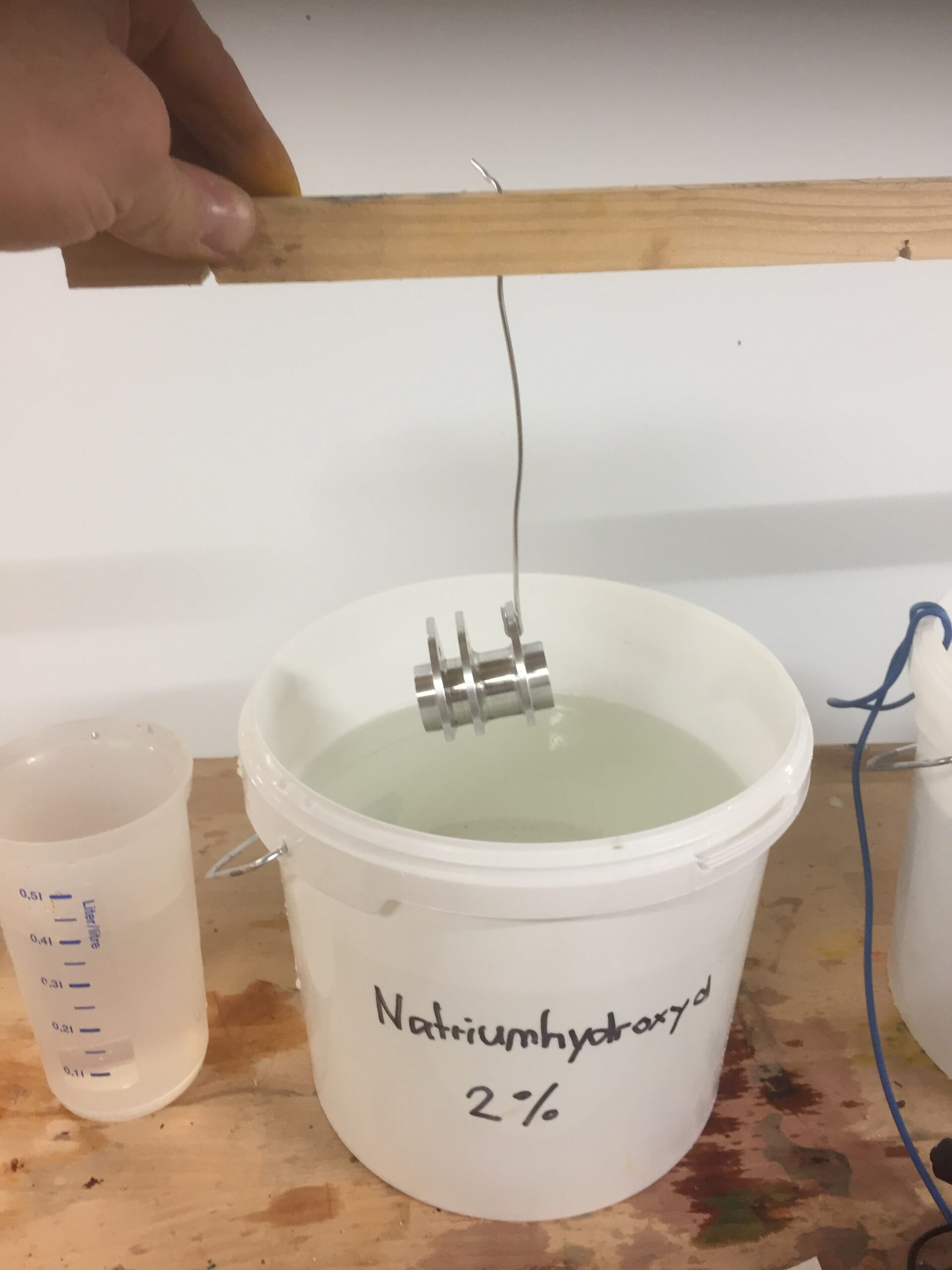

So I watched some online tutorials on the subject before getting myself plastic buckets, the required chemical ingredients and a battery charger. The first attempt was a failure as the charger went up in smoke. The second attempt with a new charger but this time with a current modulator brought success. The modulator protects the charger from overload and allows for a precise control over the thicknes of the anodizing layer.

Meanwhile the parts come out in a nice and even coating.

Zurück Weiter

Update 3.2.2021:

Before starting off I got myself smart in respect of the regulations about anodizing aircraft parts of course. I was confirmed that EASA rules permit this procedure.

A just released KITPLANES article however talks a different language.

It appears that contrary to EASA ruling anodizing is not advisable for aircraft parts.

For my part I will refrain from this procedure for critical aluminium parts in the future.

Article in KITPLANES: https://www.kitplanes.com/error-chain-15/