Nose landing gear update 6

What is the purpose of a bench test?Right, to make sure that there won’t be any unpleasant surprises. With the last parts completed and installed

What is the purpose of a bench test?Right, to make sure that there won’t be any unpleasant surprises. With the last parts completed and installed

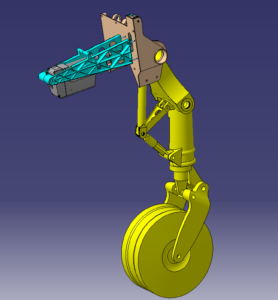

The new desing of the nose landing gear retraction mechanics requires the installation of a lock to keep it in the up position. Looking around

The main components of the nose landing gear and the retraction mechanism are assembled. After having the parts heat treated for stress relief it was

Another welding job done. It connects to the rotating shaft at the main support at the top with the Vampire gear assembly at the bottom.

Right on time for Christmas, the welding job for the nose landing gear main support is complete! Of course it didn’t work without building a

The construction of the front wheel components is in full swing. The first part, the upper gear leg section, required a welding jig to be

The past few weeks I focused on engineering work. Since the original nose landing gear retraction system proved to be problematic it needed to be

The attachment of the vertical fin is completed.The exact positioning was done by the help of a laser beam before the holes were drilled. That’s

The bottom bearing of the rudder also carries the pulleys for the cables. It is a fairly complicated structure built from 1.0mm CrMo sheet metal.

The hint from a good old Air Force colleague sounded very promising. According to him there is a familiar looking nose gear on exhibit at