Main longeron

The main longerons are each built from three sections. The rear sections again are split into an upper and a lower beam. Every section must

The main longerons are each built from three sections. The rear sections again are split into an upper and a lower beam. Every section must

How much longer ’til they come up with a Mustang pickup?! 🤣

The shape of a fuselage comes into view.The #5 bulkhead will be carrying the nose landing gear loads and is therefore built considerably stronger than

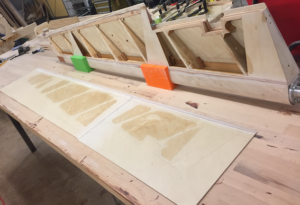

Production is running in high gear. Three bulkheads plus two stringers are finished. All nicely arranged (upside down) in a jig in which the complete

The front bulkhead and the two longeron front sections fit perfectly. The bulkhead was cut out on the ingenious table mill of a friend. Filing

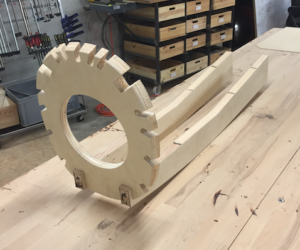

Exceptional aircraft, exceptional bulkheads. They are built in layers of segmented thin spruce sheets arranged in a circle. Topped off by plywood on both sides,

The front section of the main longeron marks the beginning of the fuselage work. The spruce boards are glued in a jig to make for

The rudder received its plywood covering on one side and has passed the final inspection of the expert. His advice to mark the areas to

The rudder leading edge is made of a molded plywood sheet with diagonal fibre orientation. The mold was fabricated to highest precision by a friend

The rudder section is separated from the fin. It is firmly held in a box to avoid any distortion while adding the leading edge structure.