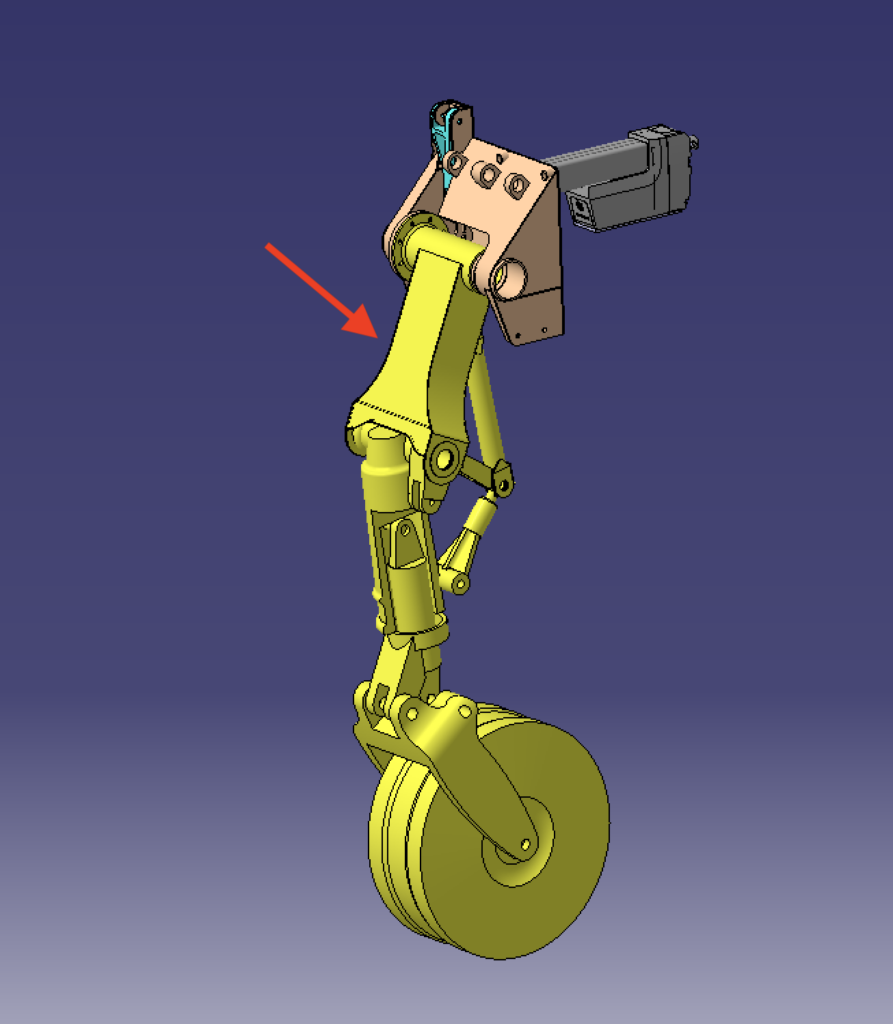

The construction of the front wheel components is in full swing. The first part, the upper gear leg section, required a welding jig to be built first. This ensures proper positioning during the welding progress.

The tube, like all the other components is built from 25CrMo4 steel. Tubing in these dimensions cannot be found anywhere. It therefore needed to be drilled and cut to size from a solid bar.

Meanwhile the first parts are held in their position by welding spots. Fitting the curved side panels proves to be a real challenge. The component will be exposed to high forces and therefore requires welding seams which must be no less than perfect. Which starts with precision fitting.