For those wondering about the lack of progress in construction over the past few months, here is the explanation:

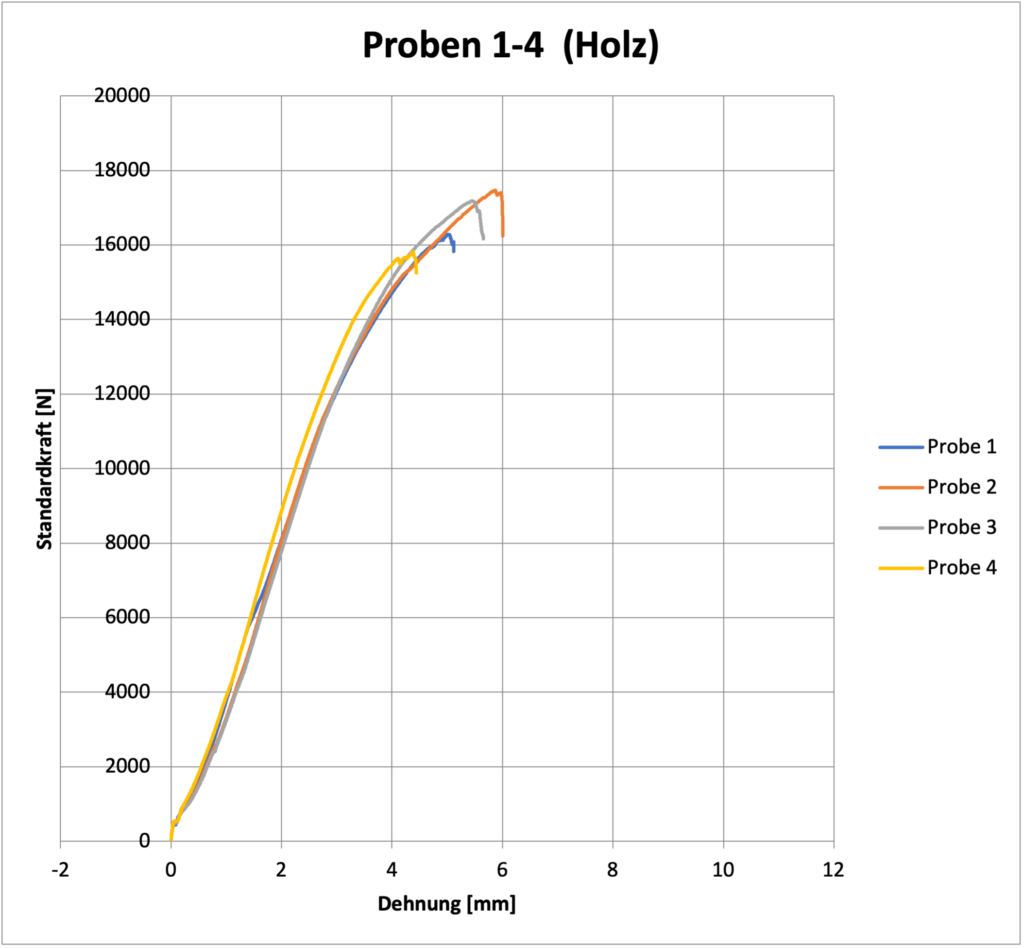

No aircraft construction project progresses without setbacks. Especially not a project where some details need to be developed before they can be built. One such detail is currently requiring a lot of effort and time: By modifying the rear fuselage from the original metal construction to a continuous wooden structure, the attachment of the vertical stabilizer also needs to be adjusted. First, the forces of the vertical stabilizer on the fuselage structure were quantified in a study by Jürg Müller (Aerodynamics RUAG Aerospace). The values turned out to be significantly high, making the introduction of forces into the fuselage a challenge.